- #Servo motor arduino model solidworks how to#

- #Servo motor arduino model solidworks driver#

- #Servo motor arduino model solidworks pro#

- #Servo motor arduino model solidworks code#

- #Servo motor arduino model solidworks Bluetooth#

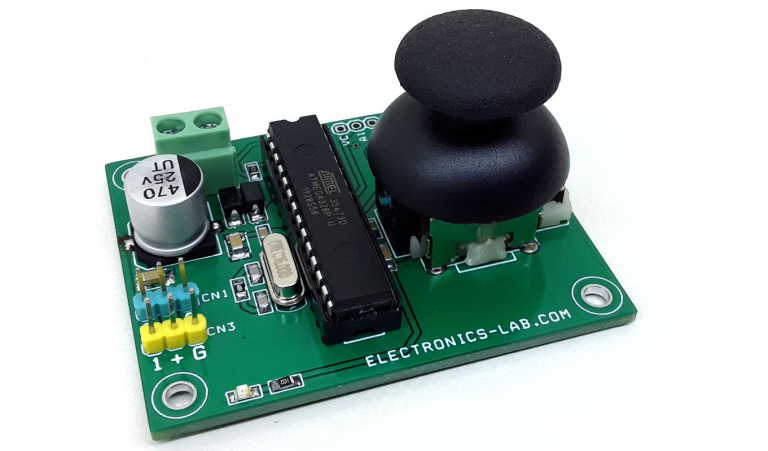

The servo's horn should move to 50 degrees from the start point. After which it will take that new angle, subtract it from the previous(current) angle and move to that amount.įor example : I adjust the angle to 50 degrees. Made using C++ in Arduino Uno board & solidworks in.

#Servo motor arduino model solidworks Bluetooth#

What I wish to get : I would like that when I set an angle, the hobby servo's horn rotates by that amount and stay there until I set a new angle for the position input. An Arduino made model with 3D printed robotic hand with servo motors & Bluetooth application to connect. e.g when i set the angle to 10 degrees, it rotates by 10 degrees every x seconds continuously. What I go to to work thus far : I got the position of the hobby servo motor's horn ( the circular part on the assembly file ) to rotate by a specific angle every x seconds ( i dont know the time interval). Lay it over and using a knife, gently tuck the cloth behind the board for the sensor and underneath the speaker so nothing but the sensor is exposed.The attachments include, the LV project file and the solidworks assembly for a hobby servo motor. Cut two circles for the PING sensors into the larger circle you have now.

And the wires can be taped down.įor the eye cut a circle out of black cloth a little bit bigger than that of the eye hole. The speaker nestles underneath the PING sensor, so underneath that toothpick from before. I painted my cardboard black for appearances and gently taped the wires attached to the LEDs in place. connect the real servo motor to arduino pin 3. Trace and cut out the shape for the body and the eye hole. Open the project file named servotest.lvproj Open the CAD file in the Project explorer (if the CAD files say out of date) right click and select synchronize to assembly. I ended up implementing a state of the art cardboard wiring harness for my project. The last part was the mount which had the servo portion placed into it and was hot glued to the project.

#Servo motor arduino model solidworks pro#

It landed just about the center and I painted it black. I created a Tower pro model in Solidworks to visualize its performance with the real servo motor, If you have any other CAD model and a working model of. I took a toothpick and wedged it into the eye socket so that it would provide extra support to the PING sensor. Hot glue the two mounts so that the holes face toward the wings and be sure to position them so that the wings can rest comfortably in a slightly open position. Start by hot gluing the head side of a screw that’s long enough to reach into the body on to the center of each of the wings. At the back left corner of where the body sits on the servo I drilled a sizable hole to run all the wires into so that they would be clustered together to give it a cleaner look but also be sure everything can reach.īody and wings. One big drill hole in the side let me run the Arduino wire out of the project and to my computer for extra power. Once that’s done place a depth that isn’t going to cause the wings and conflict with the box and screw a metal plate in underneath shimmed with washers that will hold the servo.īox prep. Knife to remove the plastic for the servo motor to sit in.

I used a few well-placed drill holes and a box Writing this position in the sense of degrees is made easier by the library.

#Servo motor arduino model solidworks code#

If it doesn’t see something the servo is written to move by increments of ten based on a pos, position integer written into the code that always counts up or down depending on which direction the bot is moving. The servo stops turning for these actions. If it sees something the LEDs are written to high in a pattern so that they light up and the speaker sounds as well. So whether or not the PING sensor notes to the Arduino that it “sees” something within 30 cm or when it doesn’t find anything within that range is going to determine what happens next within the code due to the if-statement.

#Servo motor arduino model solidworks driver#

With regard to the hardware, the PING sensor is like the driver of the code because the condition of all of the if-statements is based on what the Arduino is reading from the sensor. There is a library included for the servo motor as well as a timesTurned integer that counts up how many times the turret has shifted its position in search of an object. Continuous rotation servos allow the rotation of the shaft to be set to various speeds. Standard servos allow the shaft to be positioned at various angles, usually between 0 and 180 degrees. Servos have integrated gears and a shaft that can be precisely controlled. The major components of the code are usually directly related to the hardware: a PING sensor, a few LEDs, a speaker, and a Servo motor essentially dictate the entirety of the code. This library allows an Arduino board to control RC (hobby) servo motors.

#Servo motor arduino model solidworks how to#

Knowing how to write to the Arduino Uno components. The code is no more complex than a few if-statements and

0 kommentar(er)

0 kommentar(er)